Injection Molding

Injection Molding

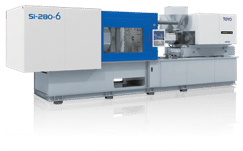

Injection molding stands as our specialty here at MSI. Furthermore, we offer a wide range of machines and capabilities to ensure every project is completed to perfection and satisfaction.

Our specialized engineers, tooling knowledge, and efficient production guarantee the ability to handle any job. In addition, we provide services such as two-shot molding, gas-assisted molding, vertical rotary molding, instrumented decoupled molding, and many others.

Machinery Features

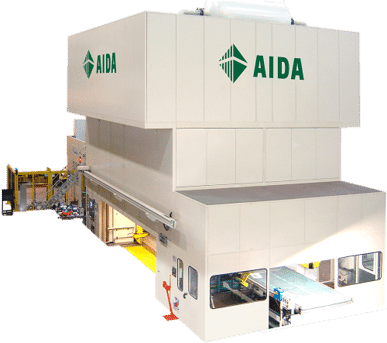

Among our four facilities, 68 injection molding machines ranging from 17 to 1320 tons are available, with shot sizes ranging from .07 oz to .142 oz. Additionally, we utilize innovative technology such as robotic equipment and an enhanced vision system, allowing us to produce exceptional, defect-free parts at a competitive cost. Furthermore, we equip each machine to provide top-tier quality.

Check out our production videos!

Grand Haven Production Video

This facility sits in Grand Haven, Michigan, covering over 20,000 square feet. Inside, one of our most advanced machines, called the horn plate cell, operates. Equipped with vision verification and eight robotic arms, the machine performs a variety of tasks. To further explore, you can watch the video to get a closer look at one of our production floors.

Ready to get started on your next project?